Cable Railing: A Complete Step-by-Step Guide

Cable Railing is a safety guardrail assembly you can install in various indoor and outdoor spaces. With this in mind, you must consider structural requirements, material options, project location, cost, building code compliances, and more to ensure a smooth installation. Understanding those elements makes you avoid problems and get the most out of your Cable Railing project.

You will find in this article helpful information about horizontal Cable Railing Systems Building Codes and how Inline Design railing products are designed to exceed those code requirements without sacrificing on design.

KEY POINTS

- How strong should Cable Railing be?

- How high should Cable Railing Posts be?

- How far apart can Cable Railing Posts be?

- How far apart should Cables be?

- How many Cables?

- What Cable is best for Cable Railing?

- Are there different types of Top Rails?

- How big to Drill Holes for Cable Railing?

- How Long to run Cable Railing?

- Do Cable Railing Rust?

- Is Cable Railing Safe?

- How to tension Cable Railing?

-

How to install Cable Railing?

- What are the Pros and Cons of Cable Railing Systems?

- What is the Cost of Cable Railing?

- What is the Cost of Cable Railing vs. Glass Railing?

- What is the Cost of Stainless Steel Cable Railing vs. Aluminum?

- Stair Cable Railing: Top Things to Consider When Installing

- Choosing Stair Cable Railing Systems

- Planning your Stair Cable Railing Installation

- Installing Safe and Stylish Stair Cable Railing

- Why Knowing Your Project Requirements is Important?

- Benefits of Professional Installation

- References

1. How strong should Cable Railing be?

The strength requirements for cable railing will depend on a variety of factors, including the intended use, the spacing between the posts, and the type of materials used in the construction.

Generally, cable railing systems are designed to meet the requirements of the International Building Code (IBC) and the International Residential Code (IRC), which specify minimum load requirements for guardrails and handrails. According to these codes, cable railing systems must be able to withstand a concentrated load of at least 200 pounds applied to any point along the top rail or a uniform load of at least 50 pounds per linear foot.

To ensure the necessary strength, cable railing systems should be constructed with high-quality materials that are specifically designed for this purpose. The cables themselves should be made from high-strength stainless steel or other corrosion-resistant alloys, and the posts and hardware should be made from materials such as aluminum or steel that are strong enough to support the loads required by the codes.

It is also important to follow proper installation techniques, including the use of proper tensioning tools and hardware, to ensure that the cable railing system is properly secured and capable of supporting the required loads. It is recommended that you consult with a professional contractor or engineer to determine the specific strength requirements for your cable railing project, and to ensure that the design and construction meet all necessary codes and standards.

2. How high should Cable Railing Posts be?

The height of cable railing posts will depend on the specific requirements of your project, as well as local building codes and regulations. Generally, cable railing posts should be tall enough to meet the height requirements for guardrails and handrails as set forth in the International Building Code (IBC) and the International Residential Code (IRC).

The IBC and IRC require that guardrails be at least 42 inches in height when located on the open sides of stairs or landings, and at least 36 inches in height when located on the open sides of walking surfaces such as decks or balconies. Handrails must also be provided on both sides of stairs, with a minimum height of 34 inches and a maximum height of 38 inches.

When designing a cable railing system, it is important to consider the height of the posts in relation to the height of the top rail. The top rail should be positioned at a height that provides a secure grip for users, while also being consistent with the height requirements for guardrails and handrails.

In addition to meeting code requirements, the height of the posts may also be influenced by aesthetic considerations and the specific requirements of the project. It is recommended that you consult with a professional contractor or engineer to determine the specific height requirements for your cable railing posts, and to ensure that the design and construction meet all necessary codes and standards.

3. How far apart can Cable Railing Posts be?

The spacing of cable railing posts will depend on a number of factors, including the specific requirements of your project, local building codes and regulations, and the type of materials used in the construction.

The International Building Code (IBC) and the International Residential Code (IRC) provide guidance on the spacing of posts for guardrails and handrails. According to these codes, cable railing posts must be spaced at intervals that will prevent a 4-inch diameter sphere from passing through any openings between the posts.

For horizontal cable railing systems, the maximum spacing between posts should be no greater than 4 feet on center. This means that the distance between the center of each post should be no more than 4 feet. However, some codes may require closer spacing based on the specific use of the railing and the potential risk of falls.

It is important to note that the spacing of the posts may also be influenced by other factors, such as the type of cable used, the tensioning method, and the specific requirements of the project. For example, some cable railing systems may require closer post spacing in areas of high wind or seismic activity.

4. How far apart should Cables be?

The spacing of cables in a cable railing system will depend on a number of factors, including the specific requirements of your project, local building codes and regulations, and the type of materials used in the construction.

The International Building Code (IBC) and the International Residential Code (IRC) provide guidance on the spacing of cables for guardrails and handrails. According to these codes, cables must be spaced at intervals that will prevent a 4-inch diameter sphere from passing through any openings between the cables. The distance between each cable should be no more than 4 inches on center.

In addition to meeting code requirements, the spacing of the cables may also be influenced by other factors, such as the type of cable used, the tensioning method, and the specific requirements of the project. For example, some cable railing systems may require closer cable spacing in areas of high wind or seismic activity.

It is important to note that the spacing of the cables may also affect the appearance of the railing system. A larger spacing between cables can provide a more open and airy feel, while a smaller spacing can provide a more solid and substantial appearance.

Before designing or installing a cable railing system, it is important to consult with a professional contractor or engineer who can assess the specific requirements of your project and ensure that the design and construction meet all necessary codes and standards.

5. How many Cables?

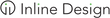

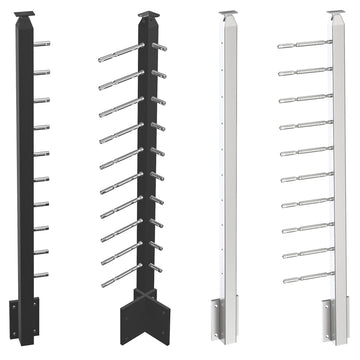

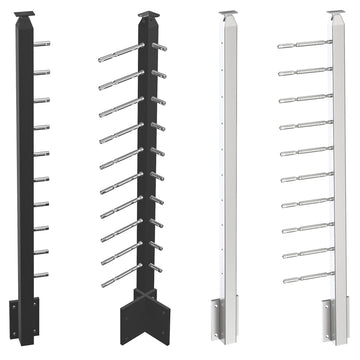

Cable Railing Systems with 36" high posts should use 10 horizontal cable runs. Cable Railing Systems with 42" high posts should use 12 horizontal cable runs. Building codes dictate that no opening shall be more than 4". The 10 and 12 cable count makes the distance between the cables 3 1/8".

6. What Cable is best for Cable Railing?

1x19 Strand Stainless Steel Wire has the smoothest construction while being strong with low flex and stretch properties. These specifications (8) make it the ideal solution for railing applications.

7. Are there different types of Top Rails?

The top rail completes the railing frame required for your Cable Railing project. Stainless steel is highly recommended for the top rails. The metal is resistant to corrosion, moisture, debris, and light impacts.

Marine-grade stainless steel is applicable to railing installed in rugged locations, such as outdoor beachfront properties, docks, outdoor decks, rooftops, etc. In addition, stainless steel top rails are suitable for indoor spaces, including commercial sites, offices, and public buildings.

Some project requirements may call for wooden top rails. To ensure long-term structural integrity, individuals should consider mounting a steel bar under the wood top rail for additional support. This implementation can help keep the wood component functional and intact, mainly as safety barriers on decks, stairs, and ramps.

8. How big to Drill Holes for Cable Railing?

Intermediate posts need to be drilled to get the cable through. Drill holes about 5/64" (or 2mm) bigger than the diameter of the used cable to avoid excessive cable deflection.

9. How Long to run Cable Railing?

The recommended cable run maximum distance is 30 feet on straight runs when using a 1/8" diameter of 1 x 19 Construction Type 316 Stainless Steel Cables. A cable run consists of a cable tensioner, a cable terminal, and a wire. The rule of thumb is that on corners, cable runs end.

10. Do Cable Railing Rust?

Cable Railing made of Stainless Steel Grade AISI 316 do not rust when properly maintained especially in environments conducive to corrosion.

Passivating Stainless Steel

Passivating Stainless Steel

Stainless Steel Railing: Is It Easy to Clean and Maintain?

Stainless Steel Railing: Is It Easy to Clean and Maintain?

11. Is Cable Railing Safe?

Cable railing systems can be safe when properly designed, installed, and maintained. However, as with any type of railing system, there are certain safety considerations that should be taken into account.

One of the main safety concerns with cable railing systems is the potential for cable breakage. While the cables used in these systems are typically made of high-strength materials, they can still be subject to wear and damage over time. To minimize the risk of cable breakage, it is important to use high-quality cables, maintain proper tension in the cables, and inspect the cables regularly for signs of wear or damage.

Another safety consideration is the spacing of the cables. The International Building Code (IBC) and the International Residential Code (IRC) provide guidance on the spacing of cables for guardrails and handrails. According to these codes, cables must be spaced at intervals that will prevent a 4-inch diameter sphere from passing through any openings between the cables. The distance between each cable should be no more than 4 inches on center.

Proper installation of the cable railing system is also important for safety. The posts used to support the cables must be properly secured and able to withstand the loads placed on them. The cables must be properly tensioned and anchored to the posts to ensure that they will not become loose or detached.

Overall, cable railing systems can be a safe and attractive option for residential and commercial applications when designed and installed properly. It is important to work with a professional contractor or engineer who can assess the specific requirements of your project and ensure that the design and construction meet all necessary codes and standards.

12. How to tension Cable Railing?

Each cable run is made from one tensioner, one terminal, and a cable. Apply a tension meter tool on the cable, then twist the tensioner hardware enough to have your desired reading on the tension meter. Repeat this process on the remaining cable runs to have equal tension on all the wires.

Pro Tips:

Pro Tips:

- Start tensioning from the middle cable and then work your way out to the top and bottom. Tension the cables equally using a tension meter.

- Avoid over tensioning the cables. See tip sheet on how to use the tension meter.

- Cut all the wires of the same run to the same length. Make sure that all the posts are leveled from all the sides.

- Make sure your handrail or top rail is installed properly before installing the cables.

13. How to install Cable Railing?

To install Cable Railing Systems, you mount the posts or balusters with 4' maximum apart. Then mount the top rail tubing to support the posts from the pulling force of the cables.

Run the cables from End posts through Middle posts to End Posts. No opening shall be more than 3 1/4". Tension the cables equally. Use Cable Cutters to cut any wire excess.

14. What are the Pros and Cons of Cable Railing Systems?

Cable railing systems offer a number of advantages and disadvantages compared to other types of railing systems. Here are some of the pros and cons of cable railing systems:

Pros:

- Aesthetically pleasing: Cable railing systems have a sleek and modern look that can enhance the appearance of any property. They are often used in contemporary and modern designs.

- Unobstructed views: The cables used in cable railing systems are thin and unobtrusive, which means they do not obstruct the view. This is particularly beneficial for properties with scenic views.

- Low maintenance: Cable railing systems are relatively low maintenance compared to other types of railing systems. They are resistant to rust and corrosion, and only require occasional cleaning.

- Durable: Cable railing systems are typically made of high-quality materials such as stainless steel or aluminum, which makes them strong and durable. They can withstand the elements and last for many years.

- Versatile: Cable railing systems can be used in a variety of settings, including residential and commercial properties, indoor and outdoor spaces, and on stairs, decks, and balconies.

Cons:

- Cost: Cable railing systems can be more expensive than other types of railing systems, particularly if high-quality materials are used.

- Installation: Cable railing systems require precise installation to ensure they are safe and secure. This may require the services of a professional contractor or engineer, which can add to the cost.

- Code compliance: Cable railing systems must meet specific code requirements to ensure they are safe and compliant. This can add to the cost and complexity of the installation process.

- Tension maintenance: Cable railing systems require regular maintenance to ensure proper cable tension. Loose or sagging cables can compromise the safety of the railing system.

- Climbing hazard: The open design of cable railing systems can make them more of a climbing hazard for young children or pets.

Overall, cable railing systems offer a number of benefits for properties where unobstructed views and a modern aesthetic are desired. However, they may not be suitable for all properties or budgets, and proper installation and maintenance are critical to ensuring their safety and durability.

15. What is the Cost of Cable Railing?

The cost of Cable Railing Systems usually ranges between $70 and $150 per linear foot. The price varies greatly depending on the material (wood is cheaper than metal) and how many corner and end posts you use. Cable Railing is moderately expensive for a railing system and more affordable than other railing types like glass and rods.

With years of experience, the Inline Design team can work with you to create an accurate quote for your Cable Railing project.

16. What is the Cost of Cable Railing vs. Glass Railing?

Glass railing is also popular among high-end homes. When it comes to visibility, these two are toe-to-toe — slim cables almost vanish from a distance, and panels of glass offer great visibility if they're treated to be glare-free. However, in terms of Cable Railing vs. Glass Railing costs, it isn't so close.

Cable handrails are often less expensive than glass, especially if you're using wooden posts. This is also true for maintenance — stainless steel railing systems prices drop quite a bit when you realize they don't need to be regularly wiped with a cleanser.

17. What is the Cost of Stainless Steel Cable Railing vs. Aluminum?

While prices vary between manufacturers, there's a clear winner in terms of Cable Railing made of Stainless Steel vs. Aluminum costs. Aluminum may be less durable, especially in saltwater environments, and require more maintenance, but it's less expensive than cable handrails. However, if you need a stronger and longer-lasting railing solution, Stainless Steel Cable Railing is a great investment.

18. Stair Cable Railing: Top Things to Consider When Installing

Stair Cable Railing Systems are a stylish way to complement the interior and exterior of a property. The discreet design and unique looks work with a wide range of décor, including modern, contemporary, and traditional themes.

A great way to update your home is by installing marine-grade stainless steel Stair Cable Railing on your staircase. This home area is often overlooked, yet it can create a focal point with a simple yet sophisticated design. For both small and large properties, a wire railing can easily open up a space. This high-quality popular railing option blends living areas and creates fluidity between different rooms in your home.

There are several essential elements to consider when installing a Stair Cable Railing system. Careful planning of your railing project will ensure a seamless and successful installation.

19. Choosing Stair Cable Railing Systems

Stair Cable Railing style will depend on your personal preferences and the area you are planning to install. There are a variety of options available that can be fitted by both DIY enthusiasts and professionals. A popular look includes steel frames and industrial styling, which works perfectly for people wanting to achieve a contemporary theme.

Other options feature Stair Cable Railing Systems with wood frames, creating a natural and subtle style. If your home is small, making the staircase an open and stylish feature can give the illusion of more space. The stairway railing does this by taking away visual barriers and contributing to an open-plan feel.

20. Planning your Stair Cable Railing Installation

There are many elements to Stair Cable Railing, but implementing this unique feature can be straightforward once you've covered the basics. The installation can be a "Do It Yourself" job, or you can seek the help of a professional. Whichever way you decide to undertake this project, ordering the railing is the next step.

Inline Design can produce Stair Cable Railing posts to your specifications if you have an idea in mind. Each part of the system is considered, from the post and rail spacing to the end caps and post railing design.

Using step-by-step guidance and providing detailed measurements can help you achieve a perfect railing system customized to your property.

21. Installing Safe and Stylish Stair Cable Railing

The right tools and guidance are essential for successful Stair Cable Railing installation. Make sure that your project complies with local building codes before you begin. Wearing protective clothing, gloves, and a breathing mask will also ensure your safety.

Here's a handy guide from Inline Design to help you with the process.

These simple yet effective documents guide you through each step of placing and installing railing parts to ensure a safe and secure staircase system.

22. Why Knowing Your Project Requirements is Important?

For large or complex projects, the installed Cable Railing system often includes handrails. It is recommended to double-check field measurements, dimensions, and finalized shop drawings to prevent bottlenecks. This crucial step can prevent delays and miscalculations during fabrication. If it is not possible to make field measurements, individuals may obtain guaranteed dimensions from their contractors.

Obtain guaranteed dimensions in writing by the Contractor—coordinate fabrication and delivery schedule of handrails with construction progress and sequence to avoid delay of railing installation.

23. Benefits of Professional Installation

Some people may prefer a professional installer for their Cable Railing Systems for that extra peace of mind. As railing is for Safety, Donnie Balvin from Inline Design explains that "It's advisable to get a professional because of this factor." Donnie also notes that "Handy DIY customers can install most of our products. But to install an entire system like our Arcadia, a welder is required since the top rail needs to be cut/mitered and welded on the job site."

Cable Railing is a practical and stylish way to make a home or business space safer.

24. References

Disclaimer: Customers are encouraged to call their local city for information about their local building codes (4). City building codes supersede national building codes. Inline Design is providing this information in an advisory capacity only. The company is not liable for any non-compliance with applicable building codes associated with railing installations.